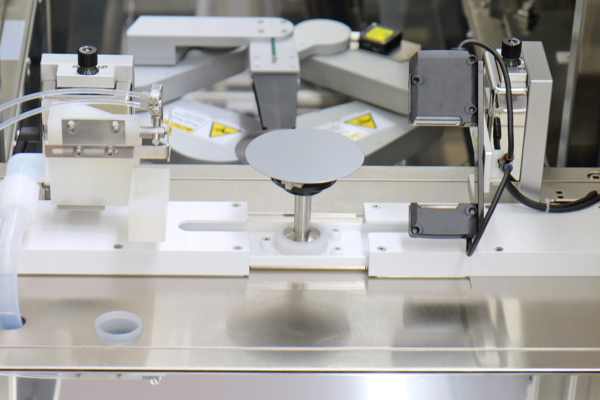

EBR

Obducat’s high performing Edge Bead Removal (EBR) technology is used to remove the build-up of material at the substrate edges after spin coating. Removal of the edge bead prevents Stepper focusing problems and any photoresist on the backside of the wafer. It also prevents ‘chipping’ of the photoresist that could cause contamination issues.

Obducat offers three types of EBR processes – standard solvent based, and SmartEBR utilizing either solvent process or UV:

- The standard solvent based EBR process uses a programmable solvent nozzle directed towards the substrate edge while the centrifugal force rinses the edge bead away.

- SmartEBR (Solvent) This also uses a programmable solvent nozzle directed towards the substrate edge. The wafer, piece or square substrate is mapped to detect its shape. Once mapped it is then transferred to the EBR nozzle and the substrate is then rotated to remove the edge bead around its edge.

- The SmarEBR (UV) exposure based EBR process is based on exposing the substrate edge and there after performing a developer process to rinse the edge bead away.