Products & solutions

Products & solutions

EITRE® Large Substrates

NIL FOR LARGE SUBSTRATES UP TO 500 x 500 mm

Nanoimprint tool for substrates up to 500 x 500 mm. This semi-automated tool enables high accuracy patterns with resolutions down to 50 nm to be replicated large substrates with excellent repeatability . The tool offers the highest possible flexibility using different imprint processes in the same equipment, allowing a wide range of materials to be used.

Highlights

Versatile semi-automatic NIL tool

Superior residual layer uniformity across the substrate area

High accuracy pattern replication for patterns down to sub-50 nm

Integrated in-line CVD anti-stick of IPS

Key Features

- The EITRE® Large Substrates NIL tool is a semi-automated lithography tool, enabling high accuracy and repeatable pattern replication down to sub 50 nm resolution.

- The EITRE® tool is particularly versatile because of the flexibility inherent in the system allowing different imprint processes to be used. The imprint processes include hot embossing, thermal NIL, UV NIL and Obducat’s patented Simultaneous Thermal and UV (STU®) process. The Eitre® tools can perform a range of imprint processes which enables the use of a wide range of imprint materials.

- The embedded SoftPress® technology ensures a uniform pattern replication over the whole substrate area in process step with excellent imprint quality. It guarantees the thinnest and most uniform residual layer over the entire substrate, enabling precise and simple downstream processing.

- The EITRE® tool is suitable for use in R&D as well as pilot production within application areas such as Micro- and Mini LED displays, LCD displays, optical devices, medical devices, security printing, solar cells, functional surfaces and others.

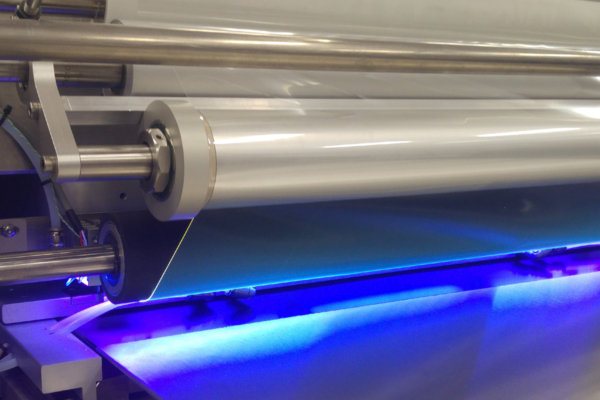

- In-line CVD anti-stick of IPS enabling higher yield and reducing material compatibility issues enabling a wider process window.

- Designed according to European safety regulations and CE Mark.

Obducat’s NIL Process Technologies

IPS® – Intermediate Polymer Stamp

The patented IPS® technology is based on making a replication of the master stamp into a soft Intermediate Polymer Stamp (IPS®). The IPS ® is then used in a second imprint step to transfer the structures onto the target substrate. The IPS® enables contamination control, increases the master stamp lifetime and makes the imprint process less sensitive to substrate contaminations and surface roughness.

SoftPress®

With Obducat’s patented SoftPress® technology, the imprint pressure is applied using compressed gas, ensuring pressure uniformity over the entire imprint area. This allows the stamp or IPS® to conform to the substrate, eliminating negative effects from thickness variations, bow or waviness. SoftPress® enables thin and uniform residual layer across the substrate, which is critical for enabling high-resolution imprinting and pattern transfer fidelity.

STU® Simultaneous Thermal and UV

The patented STU® technology combines, in one imprint sequence, the simultaneous use of thermal- and UV based imprint processes. The STU® process allows for increased polymer flow rate giving a shorter process time as well as enabling improved material compatibility and thereby a wider selection of workable imprint materials.

Automated IPS® application and demolding

The patented automated demolding function developed by Obducat for use with the patented IPS® and SoftPress® technologies makes the application of the IPS® material accurate and repeatable, ensuring that the pattern fidelity is maintained. The automated demolding function also protects the stamp from any manual handling during the imprint process.