Products & solutions

Products & solutions

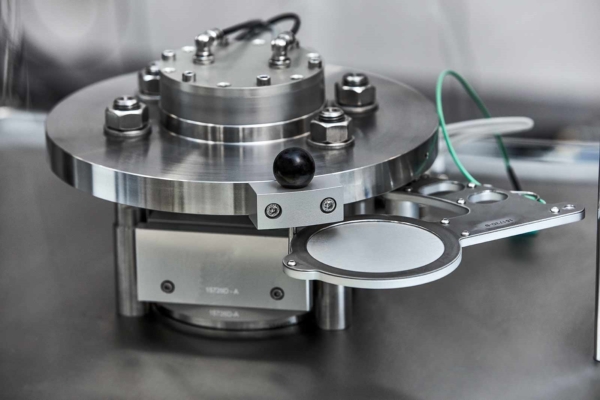

EITRE® 3 / 6 / 8

NIL FOR RESEARCH & DEVELOPMENT

An easy-to-use semi-automated and affordable range of tools for substrate sizes up to 8” x 8”, allowing pattern replication on the micro- and nanometer scale. The EITRE® tools are particularly versatile because of the multiple imprint process capabilities and the wide range of configuration possibilities.

Highlights

Versatile and flexible semi-automatic NIL tool

Thin and uniform residual layer

Capable of performing both UV- and Thermal NIL processes

Highly customizable through tool options

Wide range of UV-module options with up to 400 mW/cm2

Key Features

- The EITRE® Nano Imprint Lithography (NIL) tools offer a semi-automated and affordable lithography solution, allowing pattern replication in the micro- and nanometer range.

- The EITRE® tools are particularly versatile because of the multiple imprint process capabilities and the wide range of configuration possibilities.

- An easy-to-use semi-automatic tool with a user-friendly interface.

- The embedded SoftPress® technology ensures excellent residual layer thickness control across the entire imprint area, enabling an accurate pattern transfer and simple down stream process development.

- The flexibility of the tools allows for a variety of imprint processes to be used, such as hot embossing, thermal NIL, UV NIL and Obducat’s unique Simultaneous Thermal and UV (STU®) process.

- The EITRE® tools are suitable for research and development within application areas such as solid-state lighting, micro-optical and photonic components, bio-medical and life science devices, lab-on-chip, MEMS/NEMS and semiconductors.

- Full area imprint.

- UV-module can be configured for intensity levels from 50-400 mW/cm2 at substrate level.

- Designed according to European safety regulations and CE Mark.

Obducat’s NIL Process Technologies

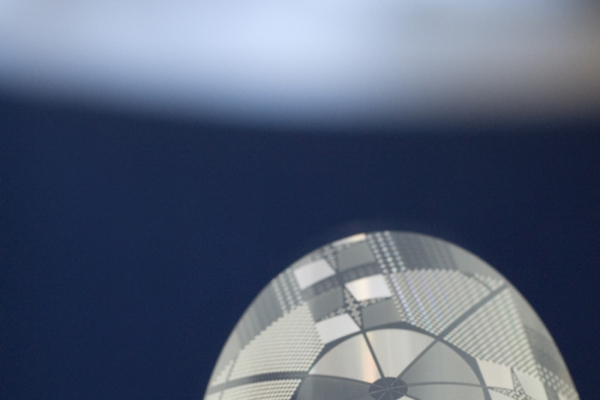

IPS® – Intermediate Polymer Stamp

The patented IPS® technology is based on making a replication of the master stamp into a soft Intermediate Polymer Stamp (IPS®). The IPS ® is then used in a second imprint step to transfer the structures onto the target substrate. The IPS® enables contamination control, increases the master stamp lifetime and makes the imprint process less sensitive to substrate contaminations and surface roughness.

SoftPress®

With Obducat’s patented SoftPress® technology, the imprint pressure is applied using compressed gas, ensuring pressure uniformity over the entire imprint area. This allows the stamp or IPS® to conform to the substrate, eliminating negative effects from thickness variations, bow or waviness. SoftPress® enables thin and uniform residual layer across the substrate, which is critical for enabling high-resolution imprinting and pattern transfer fidelity.

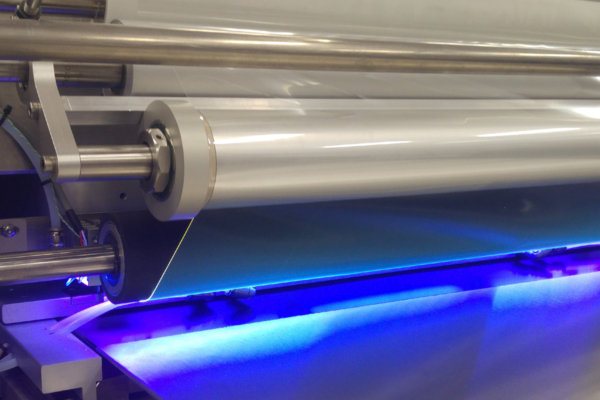

STU® Simultaneous Thermal and UV

The patented STU® technology combines, in one imprint sequence, the simultaneous use of thermal- and UV based imprint processes. The STU® process allows for increased polymer flow rate giving a shorter process time as well as enabling improved material compatibility and thereby a wider selection of workable imprint materials.