Multiple Chuck solutions – Vacuum, Low contact, Bernoulli, Centrifugal

Chuck solutions for coating:

- In case the backside has active areas the use of an edge handling chuck is recommended, with an edge exclusion of typically 4mm.

- Glass substrates are very sensitive to temperature gradients. Since vacuum substrate handling may cause such temperature gradients, Obducat offers glass substrate handling by corner suction cups with alignment pins

Chuck solutions for developing, etching, and cleaning:

- Standard wafers that are wet treated use low contact chucks, where the wafer is held in place by supporting pins. and centripetal force fixing it during the high-speed drying.

- Squared substrates are held at the corners by alignment pins using low contact chucks. The advantage of this chuck is the entire backside can be rinsed.

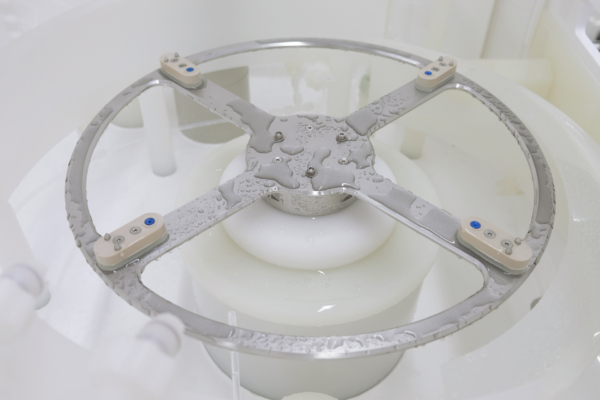

- If the backside must be protected against aggressive (etching) medias, a Bernoulli chuck can be used. This chuck blows nitrogen which protects the entire backside against chemicals. Alignment pins hold the wafer in place and enables high spin acceleration.

- If alignment pins are not allowed, a venturi chuck can be used instead. Nitrogen is injected into the chuck, creating a vacuum in the chuck center by mean of an integrated Venturi nozzle, the nitrogen blows out close to the wafer backside edges. This also protects the wafer backside against chemicals.

- Centrifugal chuck – Centrifugal force chucks are used for wet applications. They are held in place by supporting pins. The pins are combined with centrifugal force devices to hold the wafer down at higher spin speed.